We're not only moulding the future but designing a pathway through it

Innovation & Quality

We have an amazing and passionate team of professionals, entrepreneurs and technically skilled staff who are always looking forward to providing you with excellent products and services. With more than 20 years of plastic injection moulding experience, we focus on innovation and quality processes.

Quicker Turnaround

Our injection moulding capabilities range from 80 ton to 2400 ton machinery with state-of-the-art robots, allowing for small to large products to be produced to exacting customer standards. We are constantly updating our facilities to ensure quick turnaround with European-quality standards.

We Bring Ideas Home

We mould plastic components and parts for various industries such as electronic; mass transfer; automotive; mining; fibre optics and trucking. PIMMS Manufacturing moulds using engineering plastics (Glass filled Nylon, Acetal, Polycarbonate and ABS) as well as general purpose types (Polypropylene, Polyethylene- HDPE and LDPE).

Why our customers choose us

- In Operation since 2002

- 24 Hour OPERATION

- Small to large products

- World class quality & value

- COST EFFECTIVE

- Highly Qualified Trained Team

- Shorter Lead Times

- 80ton- 2400ton Low Energy Consumption Machines

- Custom Moulding

- Variety of PLASTIC Material Options

- Outstanding Service

- Inter-company Industrial Designers and Tooling

- Flexibility and Large Volumes

- Assembly Facilities

- Innovative

- INJECTION MOULDING ROBOTS

- GLOBAL AND LOCAL CUSTOMER RETENTION

- ISO 9001 Certified

Showcasing our new 2400 ton machine

Our world class facility introduced the 2400 ton injection mould machine in 2018 and is capable of manufacturing large plastic products, with a 36kg shot weight and 40 ton mould weight capacity. PIMMS Manufacturing is now one of the largest custom injection moulding facilities in Africa.

We operate 24 hours a day to shorten lead times so you can start making money with your next product

Where the magic happens

This is our world class facility situated in Laser Park, Johannesburg, South Africa.

We are as passionate as you are to get your product out into the market and that’s why we take great care to bring your ideas to life.

What our clients say

Industries We Serve

Telecommunications

Mining & Filtration Media

Trucking

Home & Hardware

Engineering

Electrical & Lighting

Automotive

Furniture

Outdoors

Electronics

Retail

Storage

Education

Sports & Recreation

Agriculture

Transportation

These are just some of the industries we are involved in and products we have made for our customers. Give us a call

and see how we can assist you in your business.

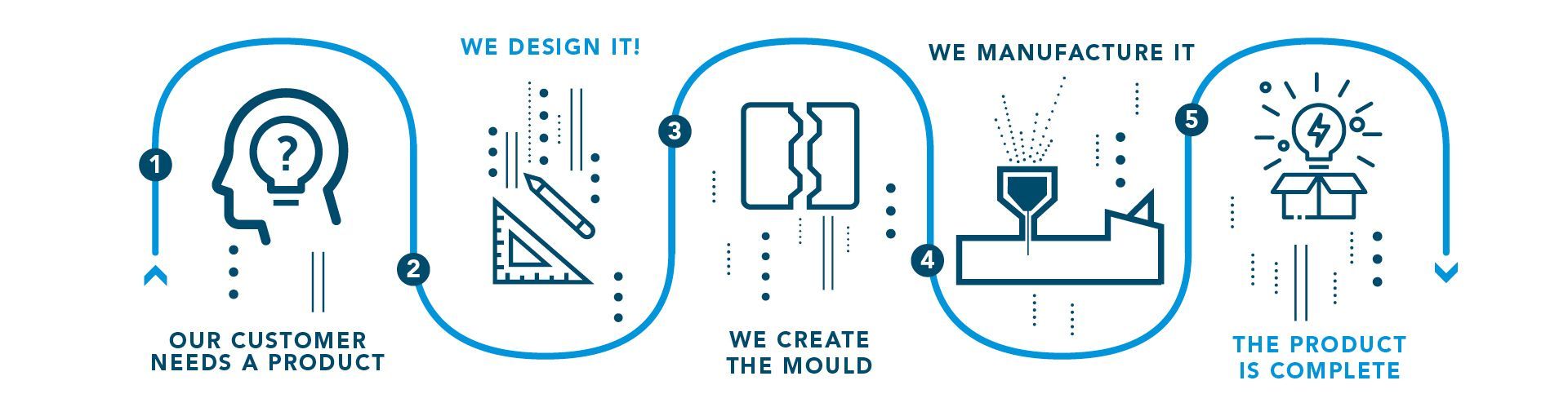

How We Can Help You